芯數(shù)×截面 (mm2) | 導體結(jié)構(gòu) 根數(shù)/線徑(mm) | 絕緣 | 護套 | |||

厚度 | 外徑 | 厚度 | 外徑 | |||

2×0.2 | 7/0.20 | 0.50 | 1.60 | 1.0 | 5.2 | 94 |

3×0.2 | 7/0.20 | 0.50 | 1.60 | 1.0 | 5.2 | 94 |

4×0.2 | 7/0.20 | 0.50 | 1.60 | 1.0 | 5.6 | 94 |

5×0.2 | 7/0.20 | 0.50 | 1.60 | 1.2 | 6.5 | 94 |

2×0.3 | 16/0.15 | 0.50 | 1.70 | 1.0 | 5.4 | 71.2 |

3×0.3 | 16/0.15 | 0.50 | 1.70 | 1.0 | 5.4 | 71.2 |

4×0.3 | 16/0.15 | 0.50 | 1.70 | 1.0 | 5.9 | 71.2 |

5×0.3 | 16/0.15 | 0.50 | 1.70 | 1.2 | 6.8 | 71.2 |

2×0.5 | 28/0.15 | 0.50 | 2.0 | 1.0 | 6.0 | 40.1 |

3×0.5 | 28/0.15 | 0.50 | 2.0 | 1.2 | 6.8 | 40.1 |

4×0.5 | 28/0.15 | 0.50 | 2.0 | 1.2 | 7.2 | 40.1 |

5×0.5 | 28/0.15 | 0.50 | 2.0 | 1.2 | 7.8 | 40.1 |

6×0.5 | 28/0.15 | 0.50 | 2.0 | 1.3 | 8.6 | 40.1 |

7×0.5 | 28/0.15 | 0.50 | 2.0 | 1.3 | 8.6 | 40.1 |

2×0.75 | 24/0.20 | 0.60 | 2.40 | 1.2 | 7.2 | 26.7 |

3×0.75 | 24/0.20 | 0.60 | 2.40 | 1.2 | 7.6 | 26.7 |

4×0.75 | 24/0.20 | 0.60 | 2.40 | 1.3 | 8.5 | 26.7 |

5×0.75 | 24/0.20 | 0.60 | 2.40 | 1.5 | 9.5 | 26.7 |

6×0.75 | 24/0.20 | 0.60 | 2.40 | 1.6 | 10.4 | 26.7 |

7×0.75 | 24/0.20 | 0.60 | 2.40 | 1.6 | 10.4 | 26.7 |

10×0.75 | 24/0.20 | 0.60 | 2.40 | 1.7 | 12.6 | 26.7 |

12×0.75 | 24/0.20 | 0.60 | 2.40 | 1.8 | 13.6 | 26.7 |

14×0.75 | 24/0.20 | 0.60 | 2.40 | 1.8 | 14.2 | 26.7 |

19×0.75 | 24/0.20 | 0.60 | 2.40 | 1.8 | 15.6 | 26.7 |

2×1 | 32/0.20 | 0.60 | 2.60 | 1.2 | 7.6 | 20.0 |

3×1 | 32/0.20 | 0.60 | 2.60 | 1.2 | 7.8 | 20.0 |

4×1 | 32/0.20 | 0.60 | 2.60 | 1.3 | 8.8 | 20.0 |

5×1 | 32/0.20 | 0.60 | 2.60 | 1.5 | 10.0 | 20.0 |

6×1 | 32/0.20 | 0.60 | 2.60 | 1.6 | 11.0 | 20.0 |

7×1 | 32/0.20 | 0.60 | 2.60 | 1.8 | 11.6 | 20.0 |

10×1 | 32/0.20 | 0.60 | 2.60 | 1.8 | 13.4 | 20.0 |

12×1 | 32/0.20 | 0.60 | 2.60 | 1.8 | 14.5 | 20.0 |

14×1 | 32/0.20 | 0.60 | 2.60 | 1.8 | 15.2 | 20.0 |

19×1 | 32/0.20 | 0.60 | 2.60 | 1.8 | 16.6 | 20.0 |

2×1.5 | 48/0.20 | 0.60 | 2.80 | 1.3 | 8.5 | 13.7 |

3×1.5 | 48/0.20 | 0.60 | 2.80 | 1.3 | 8.5 | 13.7 |

4×1.5 | 48/0.20 | 0.60 | 2.80 | 1.4 | 9.5 | 13.7 |

5×1.5 | 48/0.20 | 0.60 | 2.80 | 1.5 | 10.6 | 13.7 |

6×1.5 | 48/0.20 | 0.60 | 2.80 | 1.8 | 12.0 | 13.7 |

7×1.5 | 48/0.20 | 0.60 | 2.80 | 1.8 | 12.0 | 13.7 |

10×1.5 | 48/0.20 | 0.60 | 2.80 | 1.8 | 14.2 | 13.7 |

12×1.5 | 48/0.20 | 0.60 | 2.80 | 1.8 | 15.2 | 13.7 |

14×1.5 | 48/0.20 | 0.60 | 2.80 | 1.8 | 16.0 | 13.7 |

19×1.5 | 48/0.20 | 0.60 | 2.80 | 2.0 | 18.0 | 13.7 |

20×1.5 | 48/0.20 | 0.60 | 2.80 | 2.0 | 18.5 | 13.7 |

24×1.5 | 48/0.20 | 0.60 | 2.80 | 2.0 | 21.2 | 13.7 |

37×1.5 | 48/0.20 | 0.60 | 2.80 | 2.4 | 24.5 | 13.7 |

2×2.5 | 49/0.25 | 0.70 | 2.80 | 1.5 | 10.0 | 8.21 |

3×2.5 | 49/0.25 | 0.70 | 3.50 | 1.5 | 10.5 | 8.21 |

4×2.5 | 49/0.25 | 0.70 | 3.50 | 1.7 | 12.0 | 8.21 |

5×2.5 | 49/0.25 | 0.70 | 3.50 | 1.8 | 13.2 | 8.21 |

6×2.5 | 49/0.25 | 0.70 | 3.50 | 1.8 | 14.2 | 8.21 |

7×2.5 | 49/0.25 | 0.70 | 3.50 | 1.8 | 14.2 | 8.21 |

10×2.5 | 49/0.25 | 0.70 | 3.50 | 1.8 | 16.8 | 8.21 |

12×2.5 | 49/0.25 | 0.70 | 3.50 | 1.8 | 18.2 | 8.21 |

14×2.5 | 49/0.25 | 0.70 | 3.50 | 2.0 | 19.5 | 8.21 |

19×2.5 | 49/0.25 | 0.70 | 3.50 | 2.2 | 22.0 | 8.21 |

24×2.5 | 49/0.25 | 0.70 | 3.50 | 2.4 | 26.4 | 8.21 |

37×2.5 | 49/0.25 | 0.70 | 3.50 | 2.5 | 29.5 | 8.21 |

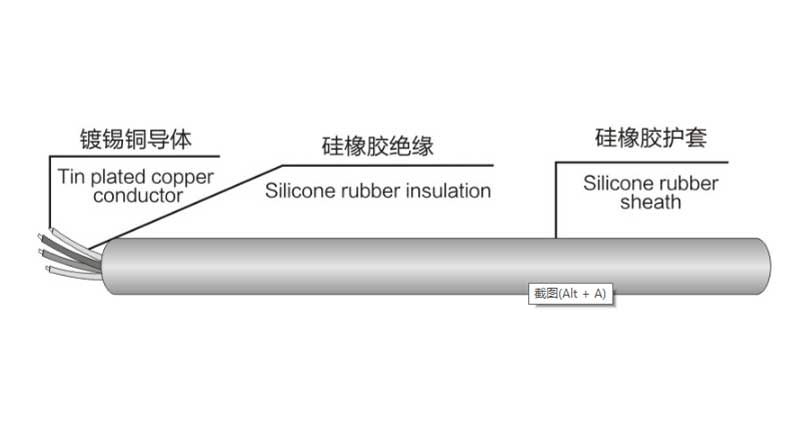

硅橡膠絕緣高溫電纜 200℃ YGZ

Executive standard: Q / irmv2-2008

Rated voltage: 600V

Working temperature: - 60 ~ + 200 ℃

Conductor: stranded tinned copper wire

Insulation: silicone rubber

Sheath: silicone rubber

Color: red, yellow, blue, white, black, brown, green, etc.

Product performance: it can be used in long-term humid environment, with excellent electrical performance, waterproof and mold resistance. Excellent bending performance, the minimum bending radius is 16 times of the outer diameter of the cable, and it can be moved. It is applicable to various mobile motors with AC rated voltage of 600V and below, steel, aviation, power plant, petrochemical and other high-temperature environments.

Delivery requirements: according to the contract agreement of both parties, it is allowed to deliver short sections of no less than 10m, and the quantity shall not exceed 10% of the total length of delivery.

Product technical parameters

中文

中文 English

English 021-63520708

021-63520708