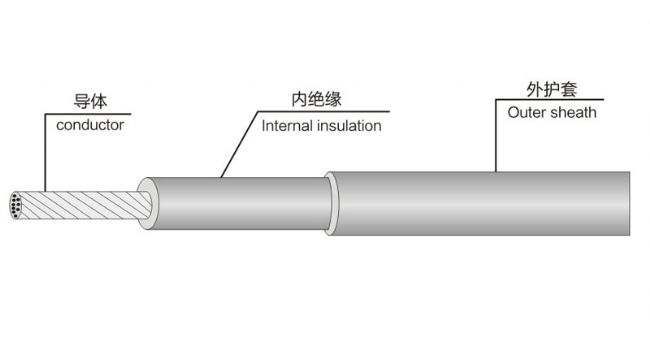

Conductor: multi strand oxygen free copper wire or tinned copper wire

Insulation: Polyurethane TPU

Voltage: 450V / 750V

Operating temperature range: - 40 ℃ + 105 ℃

1. Flexible tensile, finely twisted ultra-fine oxygen-free bare copper wire, to ensure the good conductivity of the cable, and at the same time to ensure its own flexibility and flexibility

2. Wear resistant, bending resistant and anti twisting, ensuring that the core can not be used for bending and moving back and forth, and anti-interference (shielding optional)

3. Tensile, safe and long service life - high strength galvanized steel wire bearing + jute rope filling + special non-woven fabric wrapping and buffering ensure the service life of the cable (steel wire bearing is optional) and its use is safer.

4. Temperature resistance, oil resistance and tear resistance - the new polyurethane TPU special outer sheath ensures that the cable maintains its unique characteristics during use.

Purpose: it is a special cable used for the control and power supply system of the reel and reel. It is suitable for the situation with high mechanical stress, especially tensile and torsional stress at the same time. It can be retracted with the guide of the drag shaft or other similar devices. For example: motor driven drum, spring controlled drum, lifting system and some frequently bending occasions such as woodworking machinery, machine tool processing equipment, logistics transportation system, lifting airport, etc. The reinforcing element integrated in the cable can withstand the tensile load and the gravity generated by high-speed operation. The reel cable can be installed in dry or wet industrial environment due to its special structural design and special outer sheath material.

Wire specification

| 標準截面(mm2) | 導(dǎo)體結(jié)構(gòu) 根數(shù)/線徑(mm) | 內(nèi)絕緣厚度(mm) | 外絕緣厚度(mm) | 20℃時導(dǎo)體直流電阻(Ω/km) | 包裝長度(m) |

| 1.0 | 32/0.20 | 0.4 | 0.5 | 18.4 | 100 |

| 1.5 | 30/0.25 | 0.4 | 0.5 | 12.3 | 100 |

| 2.5 | 49/0.25 | 0.5 | 0.6 | 7.36 | 100 |

| 4.0 | 56/0.30 | 0.5 | 0.6 | 5.09 | 100 |

| 6.0 | 84/0.30 | 0.6 | 0.7 | 3.06 | 100 |

| 10 | 84/0.40 | 0.7 | 0.8 | 1.85 | 100 |

| 16 | 126/0.40 | 0.8 | 0.9 | 1.15 | 100 |

| 25 | 196/0.40 | 0.8 | 1.1 | 0.736 | 100 |

| 35 | 276/0.40 | 0.90 | 1.2 | 0.525 | 100 |

| 50 | 396/0.40 | 1.0 | 1.4 | 0.368 | 100 |

| 70 | 360/0.50 | 1.2 | 1.5 | 0.262 | 100 |

| 95 | 475/0.50 | 1.2 | 1.5 | 0.193 | 100 |

| 120 | 608/0.50 | 1.4 | 1.6 | 0.153 | 100 |

中文

中文 English

English 021-63520708

021-63520708